No question: liquid nitrogen N2 is expensive. High transport and storage costs as well as long-term supply contracts result in significant expenses. Generating nitrogen independently therefore has many advantages: First of all, it saves a lot of money in the long term. Second, you will not be dependent on any liquid gas manufacturer. Thanks to highly efficient on-site nitrogen generation, you will always produce nitrogen in exactly the purity your application needs. And the investment will pay off after just a few years.

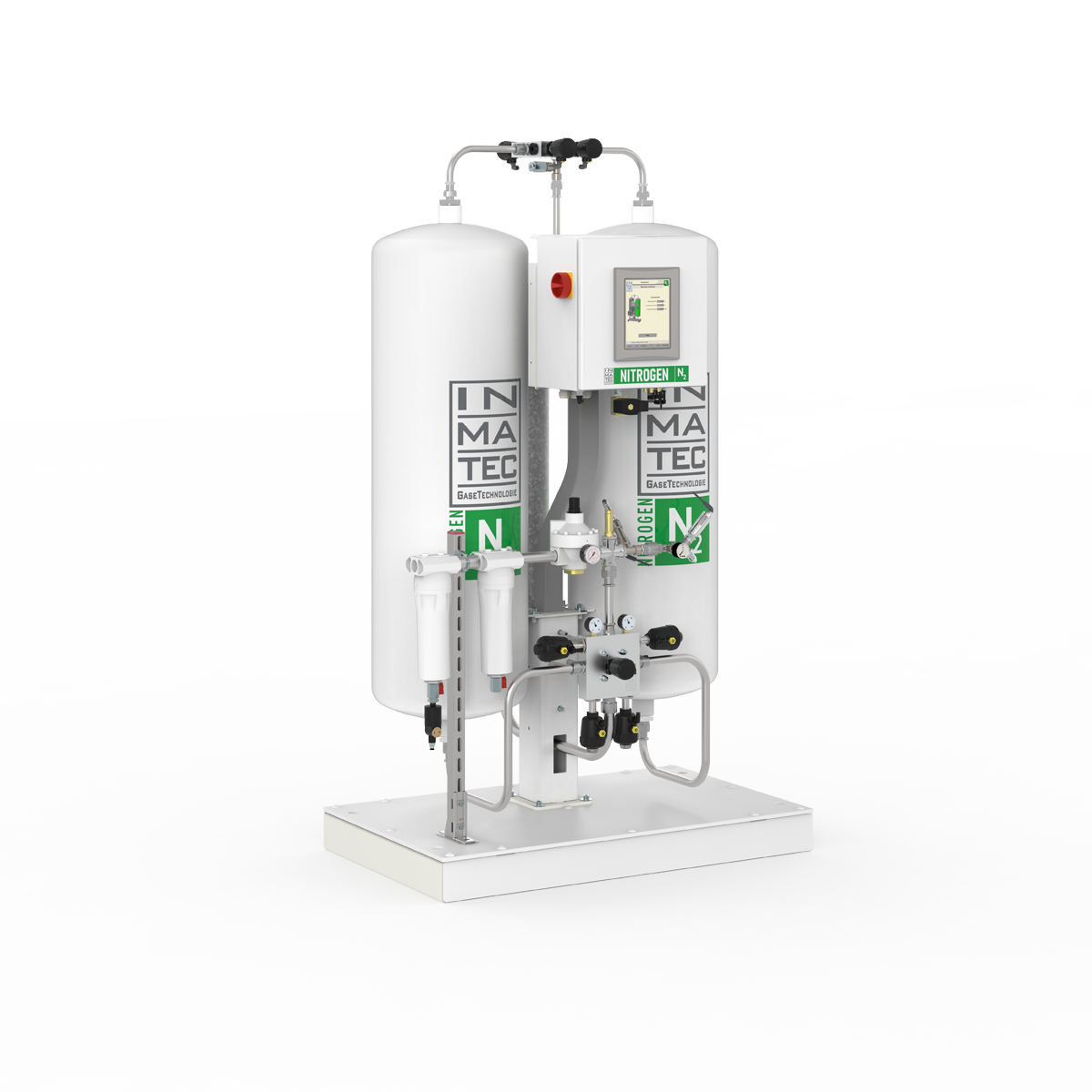

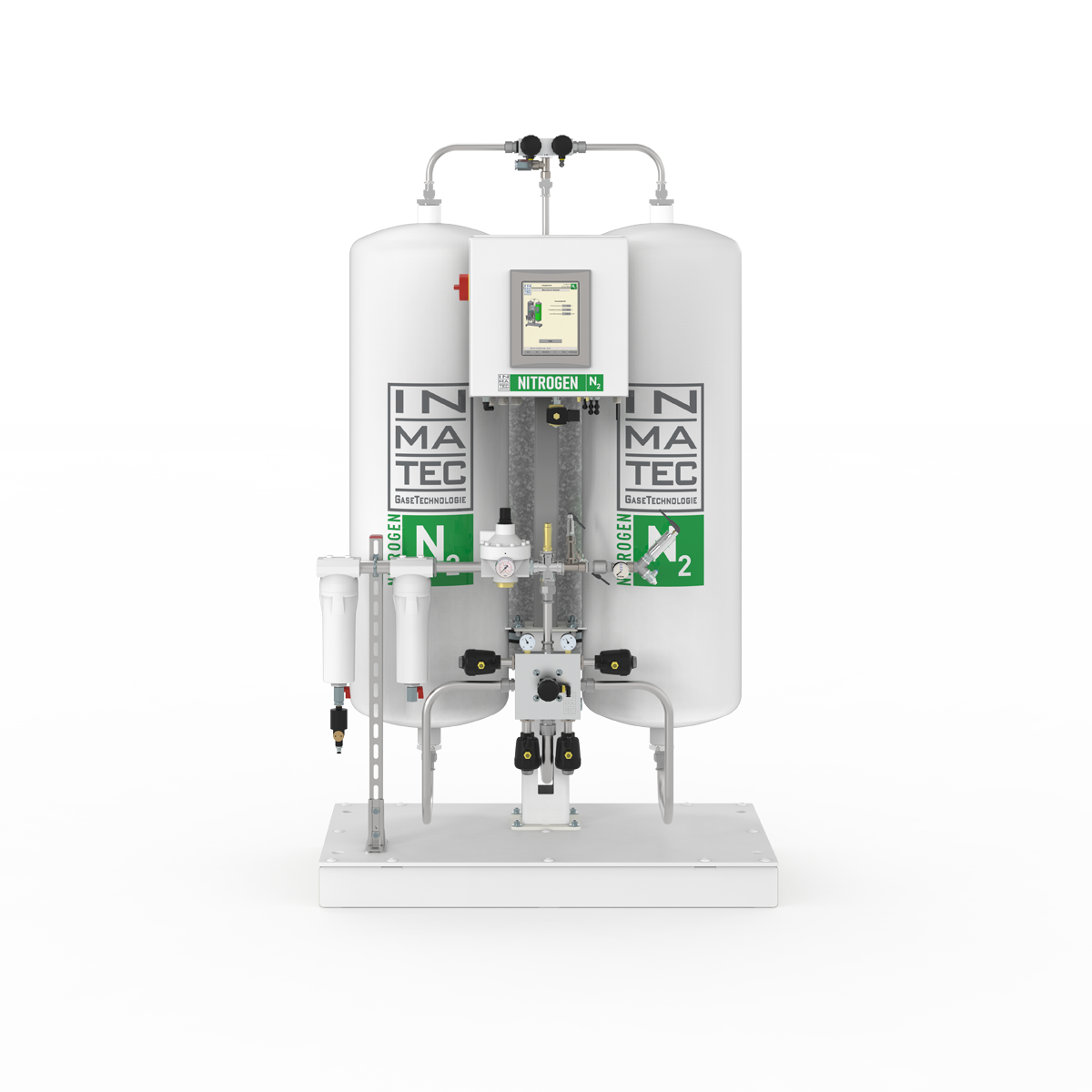

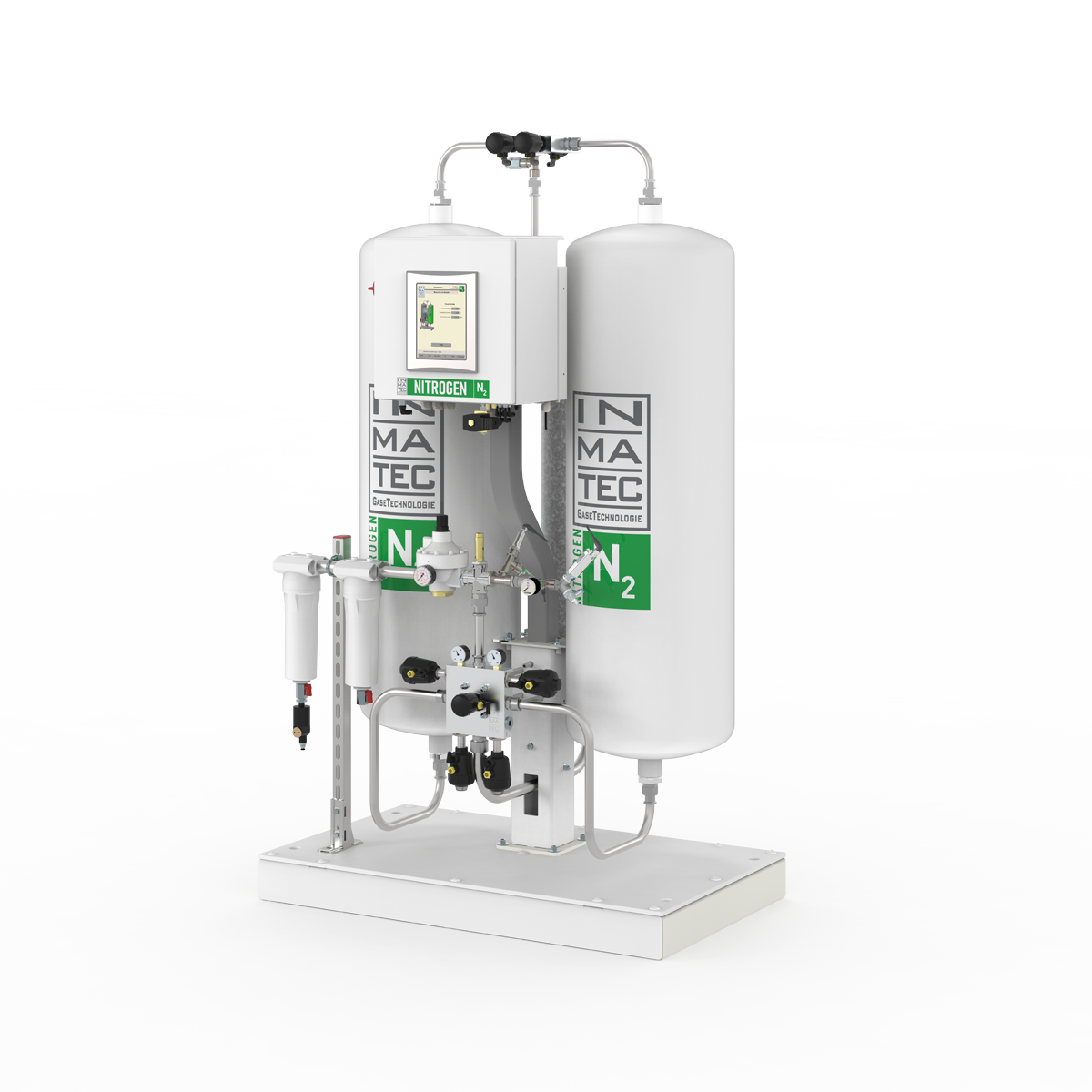

Produce nitrogen based entirely on your individual requirements using the Inmatec nitrogen generator. Rigid, inflexible supply contracts are now a thing of the past. These generators allow individual adjustment of free air delivery, output and purity, particularly quickly as well as flexibly and without any problems. Not only is the system highly efficient, but it can also be flexibly modified or upgraded in the field.

During start-up or a minor decrease in product purity, the receiver is flushed with nitrogen until the required purity class has been reached – until then, product gas of lower quality will be released via the purging valve. Only when the desired purity has been reached, will the generator open the nitrogen outlet.

This ensures a constantly high and consistent product quality and is therefore particularly suitable for sensitive applications, in the food and pharma industry for example. At a great price, Package Option 1 combines AutoPure Technology with a pressure sensor to monitor the generator’s intake pressure and a flow sensor to continuously monitor the flow quantity.

Using various sensors (including zirconium oxide sensor), the EEC constantly monitors the nitrogen requirements and purity quality of the produced gas. The expected requirement is forecast based on the current requirement profile. At full load, the generator runs at continuously high capacity. In the event of fluctuating consumption, the generator’s control reduces power and switching cycles, which leads to a significant saving with regard to purge air losses, considerably lower air consumption and thus maximum energy savings. Energy-intensive applications (large-scale plants) with fluctuating demand in particular will benefit from this solution. At a great price, Package Option 2 includes Package Option 1 supplemented with an additional temperature sensor and a pressure dew point sensor to continuously monitor compressed air temperature and humidity at the generator inlet.

The base load switching function controls two redundant supply systems. One system is in charge of the master function, while the second system manages the slave function. Switching between the two systems is automatic and is controlled by pressure and flow. Thanks to this redundancy, supply is guaranteed at all times, and in the event of necessary surplus production, capacities can be flexibly adapted to the additional requirement and optimised. Furthermore, uniform utilisation increases generator service life. Even required servicing will not necessarily lead to downtimes because a backup system is available.

If needed, the availability or reliability of the system can be increased by using a redundant valve block in the generator’s inlet and outlet. Ball valves allow switching to second (redundant) pipework during generator operation. In most cases, a fault involves the process valves. The valve block therefore covers redundancy in about nine out of ten cases. The switch takes place manually. Process valves can be cleaned or replaced without system downtimes. This results in easy, maintenance-friendly and cost-effective redundancy compared with two parallel systems.

| PNK Model | Purity | H2 KAT Model | Purity | Flow Capacity N2 Nm3/h |

|---|---|---|---|---|

| PNK 150 | 3.0 | H220 | 5.0 | 20 |

| PNK 270 | 3.0 | H240 | 5.0 | 40 |

| PNK 350 | 3.0 | H260 | 5.0 | 60 |

| PNK 500 | 3.0 | H280 | 5.0 | 80 |

| PNK 750 | 3.0 | H2100 | 5.0 | 100 |

| PNK 1000 | 3.0 | H2150 | 5.0 | 40 |

| PNK 1500 | 3.0 | H2200 | 5.0 | 60 |

| PNK 2000 | 3.0 | H2300 | 5.0 | 80 |