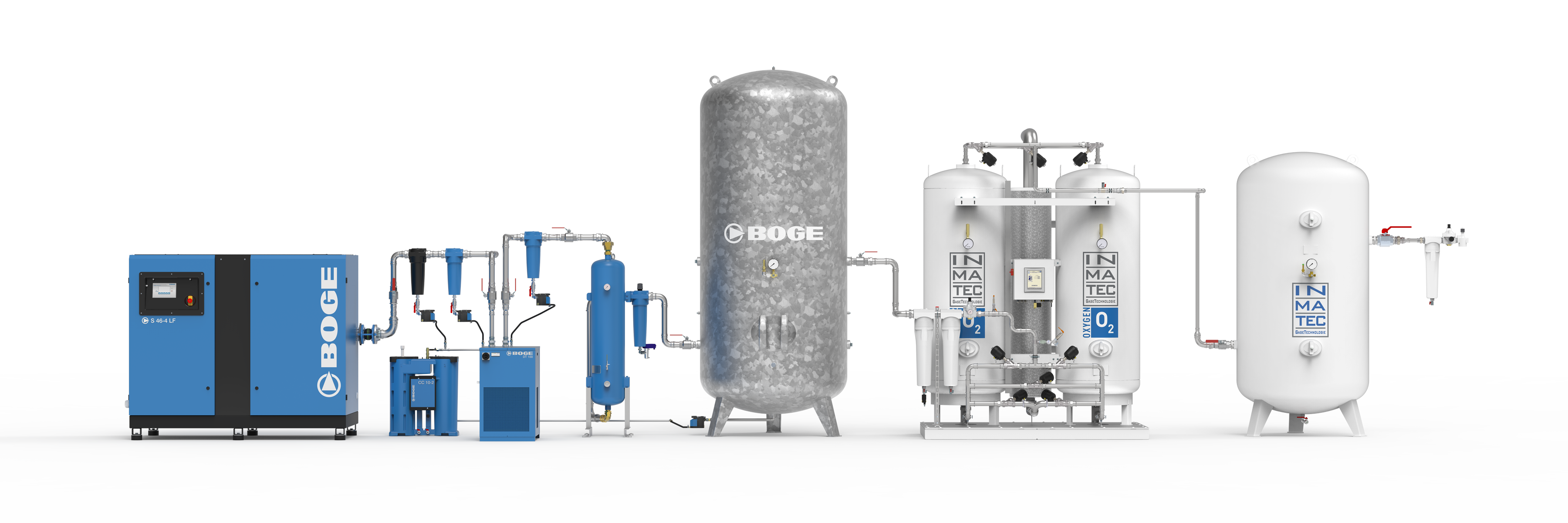

Generating oxygen independently instead of buying it – those who decide to produce it themselves not only save money but also remain independent of liquid gas manufacturers. After all, liquid oxygen is expensive. High transport and storage costs as well as long-term supply contracts create additional expenses. With highly efficient onsite oxygen generation, you will not only be independent but you will also produce exactly the purity your application requires – with complete transparency onsite. Many systems will pay off after just a few years. An investment that will be quickly noticeable in your budget.

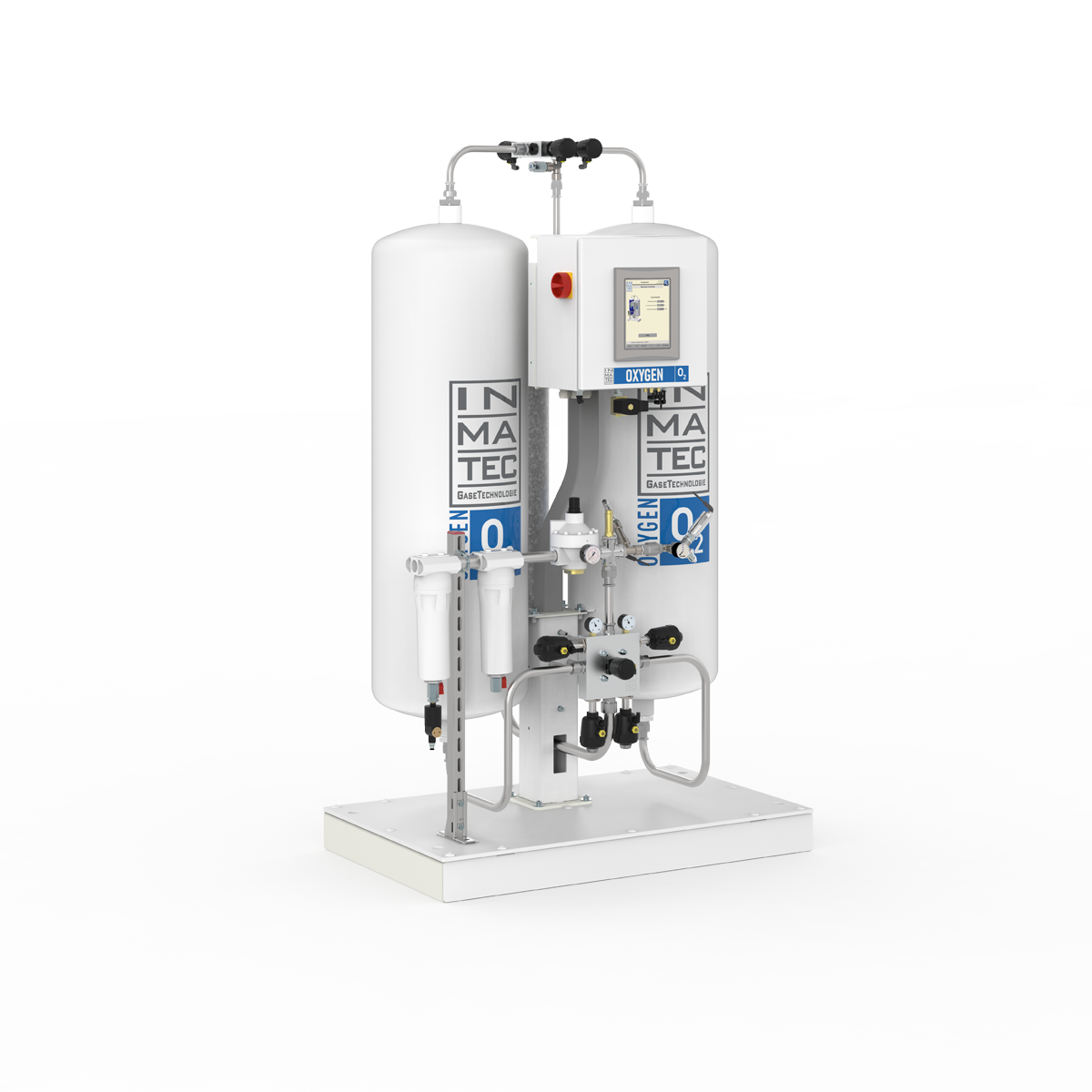

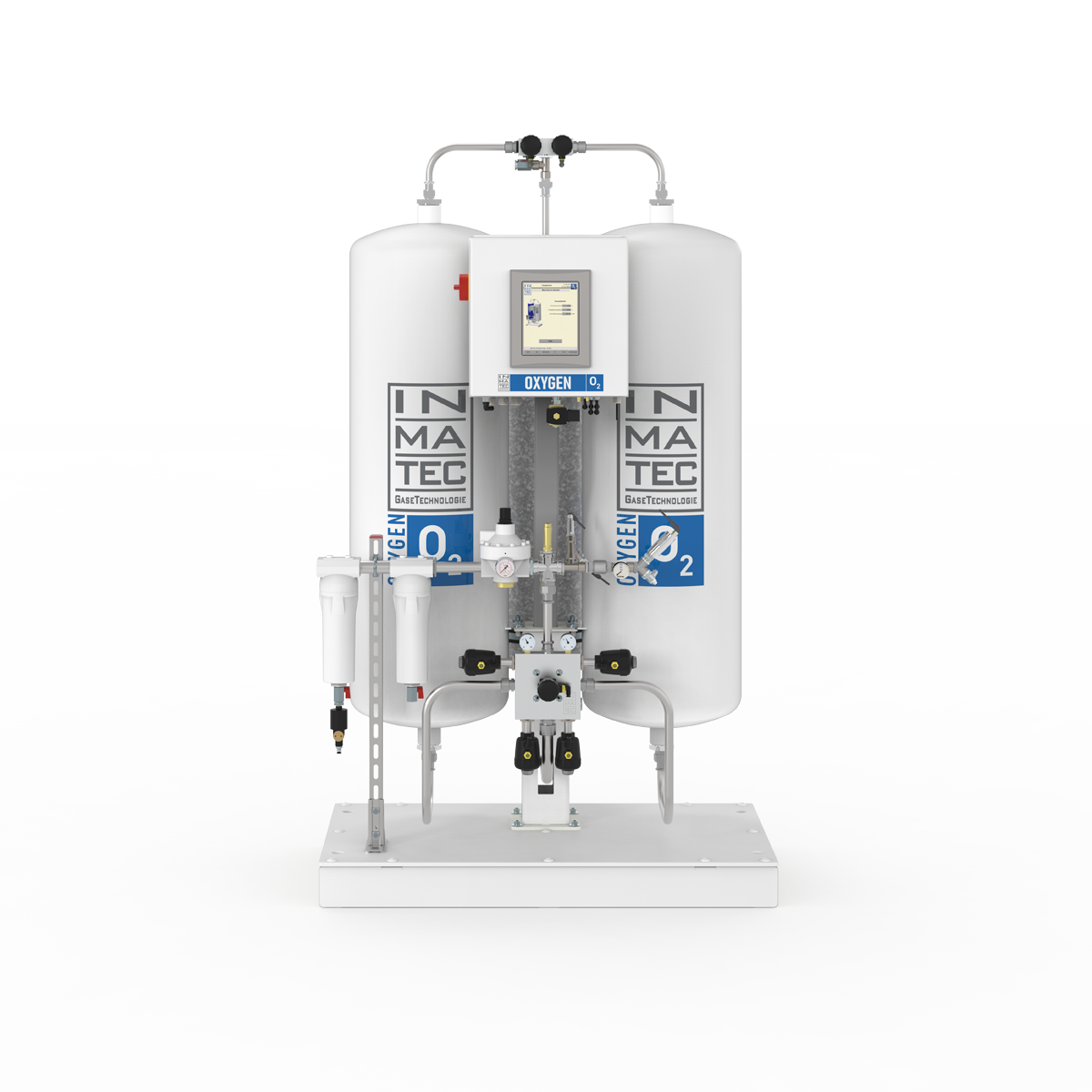

During start-up or a minor decrease in product purity, the receiver is flushed with oxygen until the required purity class has been reached. Only then will the generator open the oxygen outlet and make the oxygen available at the required purity. The product gas of lower quality is extracted via the rinsing valve until the required purity has been reached. This ensures a constantly high and consistent product quality and is therefore particularly suitable for sensitive applications in the pharma and medical industry.

Our quality promise at an attractive price.

Package option 1 combines AutoPure Technology with a pressure sensor to monitor the generator’s intake pressure and a flow sensor at the generator’s outlet to continuously monitor the flow quantity.

Your benefits: Consistently high purity, a long service life and maximum operational safety at a great price.

The base load switching function controls two redundant supply systems. One system is in charge of the master function, while the second system manages the slave function. Switching between the two systems is automatic and is controlled by pressure and flow. Thanks to this redundancy, supply is guaranteed at all times, and in the event of necessary surplus production, capacities can be flexibly adapted to the additional requirement and optimised. Furthermore, uniform utilisation increases generator service life. Even required servicing will not necessarily lead to downtimes because a backup system is available.

If needed, the availability or reliability of the system can be increased by using a redundant valve block in the generator’s inlet and outlet. Ball valves allow switching to second (redundant) pipework during generator operation. In most cases, a fault involves the process valves. The valve block therefore covers redundancy in about nine out of ten cases. The switch takes place manually. Process valves can be cleaned or replaced without system downtimes. This results in easy, maintenance-friendly and cost-effective redundancy compared with two parallel systems.

Sustainable production has great influence on the competitiveness of a company. Sustainable management within the sense of Corporate Social Responsibility (CSR) requires investments for the economic use of natural resources and the protection of both climate and environment.

The investment in environmentally friendly technologies initially requires money but it will pay off. By reducing carbon dioxide (CO2) emissions as part of production and transport, you will make a contribution to climate protection.

Your partner in oxygen supply Inmatec has been developing and producing nitrogen and oxygen generators since the company’s foundation in 1993. We supply tailor-made solutions to the whole world and are now one of the international market leaders. With our PSA systems, membrane systems and H2KAT subsequent cleaning to generate the highest purity classes, we meet the most demanding requirements. The high-pressure solutions and container design guarantee efficiency, quality and independence. With our many years of experience and global presence, Inmatec’s “Made in Germany” seal represents absolute peak performance. Situated in Herrsching, our company has been part of the BOGE Group since 2023 and can, in addition to our own team, make use of its international sales and service organisation. This means we are able to work for you even more effectively and purposefully. Discover the fascinating world of onsite technologies. In addition, companies benefit economically from significant savings in energy costs, reduced energy taxes and government subsidies. In this way, investments in Inmatec O2 generation systems usually pay off very quickly.